Residual oil content measurement OILCHECK according to ISO 8573 - mobile solution

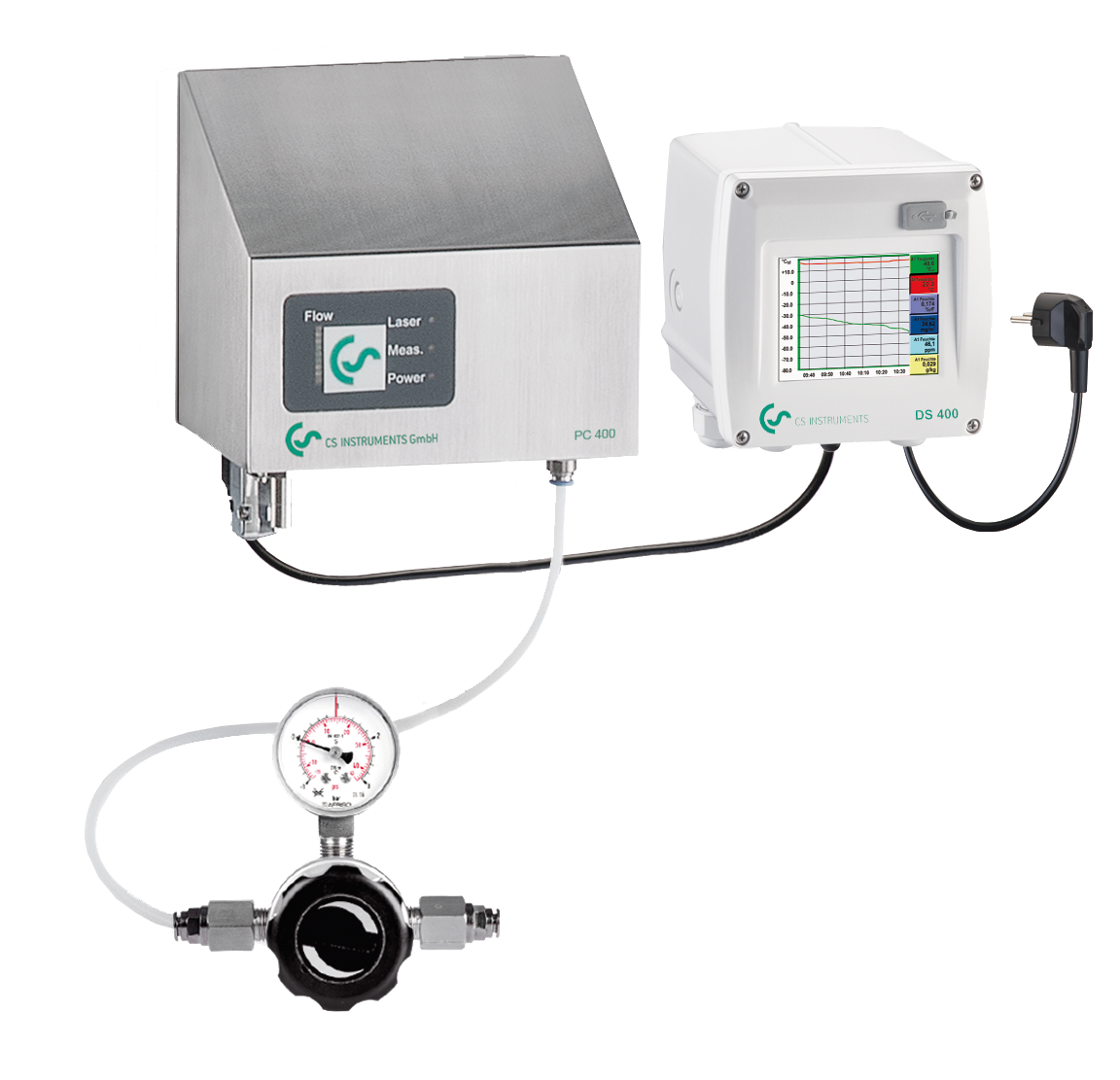

The residual oil content sensor OILCHECK measures the vaporous residual oil content in the compressed air. For a mobile solution we offer you a combination with the particle counter PC 400 and mobile chart recorder DS 500 mobile.