OIL CHECK 500

The monitoring system for high-precision measuring of the Vaporous Residual oil content of Compressed air and Nitrogen.

Why use an oil-free Compressor?

Oil contamination in Compressed air can cause production downtime and loss of quality, as the pipeline network, production facilities and end products can be contaminated. Oil-free Compressed air is therefore particularly important in the food and beverage industry, the pharmaceutical industry and in medical applications. Other applications include chemical and petrochemical process engineering, electronics and semiconductor manufacturing, automotive painting, the paper industry and textile manufacturing. In industries such as brewing, where Nitrogen is used to prevent oxidation and maintain pressure, the purity of the compressed air is crucial. Oil-free Compressed air, combined with Nitrogen generators, can ensure product quality and reduce costs by producing Nitrogen in-house.

Oil-free versus Oil lubricated

When selecting a Compressor, it is important to differentiate between "oil-lubricated" and "oil-free" solutions. Both types of compressor supply Compressed air, but differ in their lubrication. Oil-lubricated Compressors use oil to lubricate the internal components, while oil-free Compressors use self-lubricating or pre-lubricated materials to keep the parts moving efficiently.

When is "oil-free" the right choice?

Oil-free Compressors are particularly suitable for industries where even the smallest amounts of Oil can damage equipment or spoil products. This applies to the pharmaceutical, food and beverage, electronics, laboratory and similar industries. However, if Oil is not a critical factor in your Applications, an oil-lubricated or "technically oil-free" system could be an option. This is because oil-free Compressors are more expensive to purchase and more energy inefficient than oil-lubricated Compressors. It is therefore crucial to ensure that the Compressed air from your Compressors meets your quality requirements to avoid unnecessary costs and energy losses.

Limitations of oil-free Compressors

Oil-free Compressors do not necessarily deliver ISO quality class 1 compressed air, as they draw in ambient air that may contain hydrocarbons. Activated carbon filters and activated carbon absorbers are often installed to remove these hydrocarbons. These filters become saturated over time and can release hydrocarbons again.

Types of intake for air compressors

Compressed air treatment to comply with ISO 8573-1 classes

Several steps are necessary to improve the Compressed air quality after compression and achieve higher ISO 8573-1 classes:

These measures ensure high Compressed air quality and meet the requirements of the ISO 8573-1 standard.

Continuous monitoring and measuring

With the OIL CHECK 500, you can continuously measure and document the purity of your Compressed air and prevent expensive production downtime. Measuring helps you to assess the effectiveness of your compressed air treatment and to change the activated carbon filter/bulk filter as required.

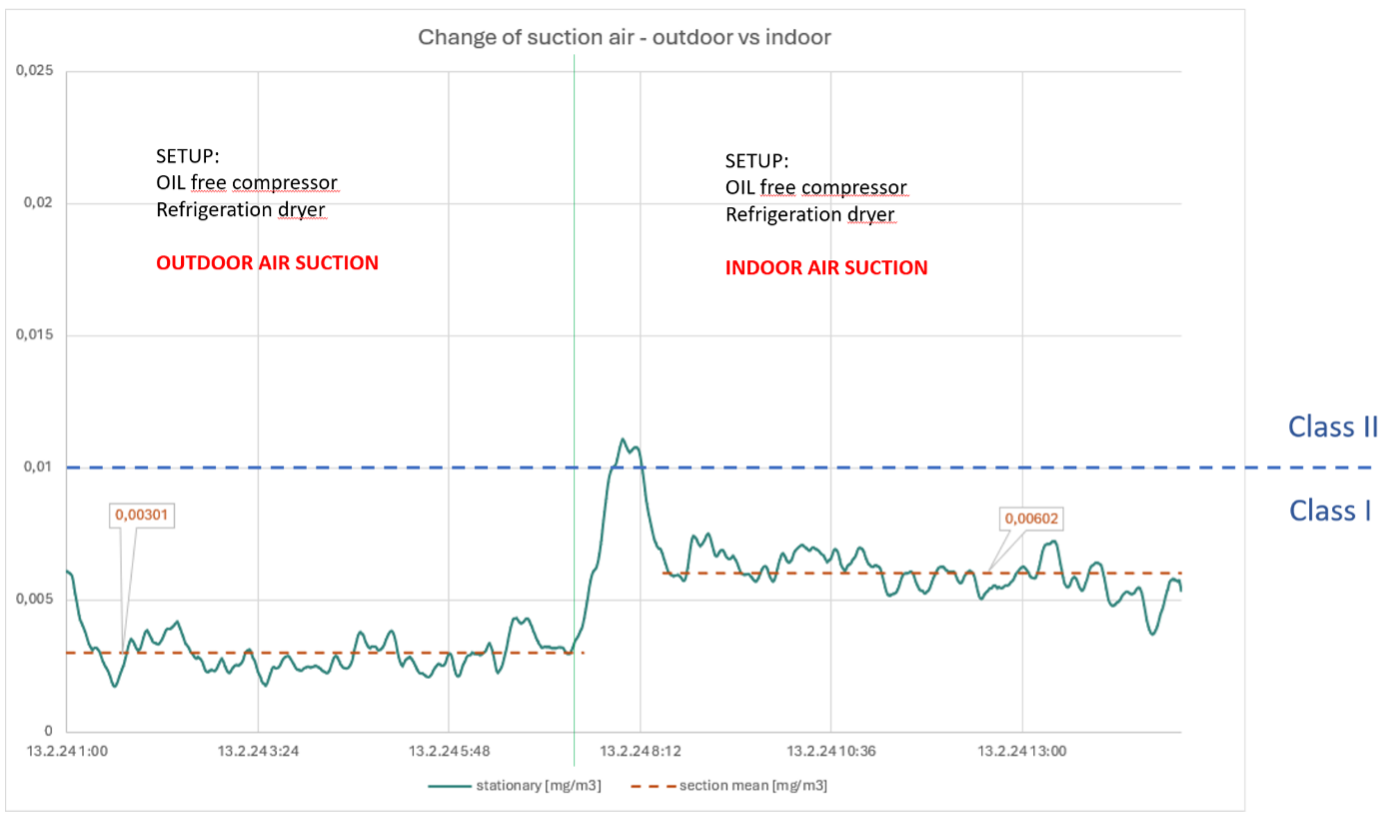

The graph shows the Measured values of the OIL CHECK 500 after installation and switching the intake from external to internal intake in a compressed air system with an oil-free Compressor and Refrigeration dryers.

Results:

With its high sensitivity and three calibration points in class 1, the Oil Check 500 precisely indicates even minimal changes in the oil vapor values. Despite the increase, the values remain within the highest cleanliness class, which underlines the importance of the intake and the need for continuous monitoring to ensure the highest quality standards.

| SCENARIO | PERMITTED |

(1) Compressor, (2) Tank, (3) Ref. dryer,(4) Ad. Dryer,(5) Filter stage incl. Act. Carbon |  |

(1) Compressor, (2) Tank, (3) Ref. dryer, (4) Filter stage with activated carbon |  |

(1) Compressor, (2) Tank, (3) Ad. Dryer, (4) Filter stage with activated carbon |  |

(1) Compressor, (2) Tank, (3) Catalytic converter, (4) Ref. dryer, (5) Filter stage |  |

(1) Oil-free Compressor, (2) Tank, (3) Refrigeration dryer, (4) Filter stage |  |

| SCENARIO | NOT PERMITTED |

(1) Oil-free Compressor, (2) Tank, (3) OIL CHECK 500 |  |

(1) Compressor, (2) Tank, (3) OIL CHECK 500 |  |

Would you like to continuously monitor the quality of your Compressed air?

Use the OIL CHECK 500 to continuously monitor your Compressed air quality and ensure that your production always meets the highest standards. You can find more information on the product page or call us for a personal consultation and customized solutions for your compressed air monitoring. Take the initiative now and optimize your production processes!