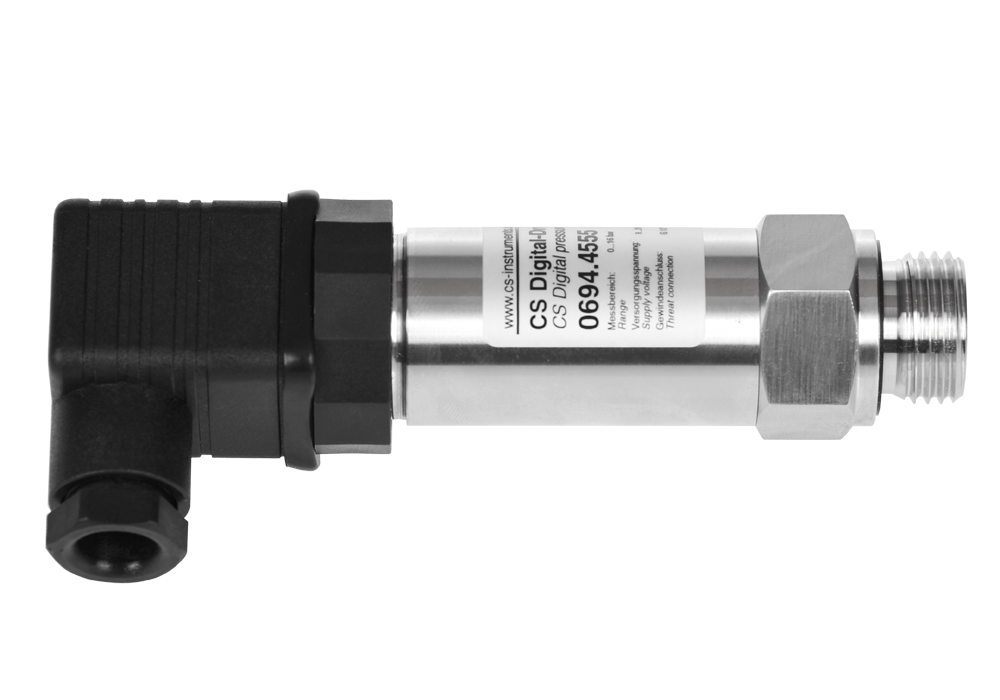

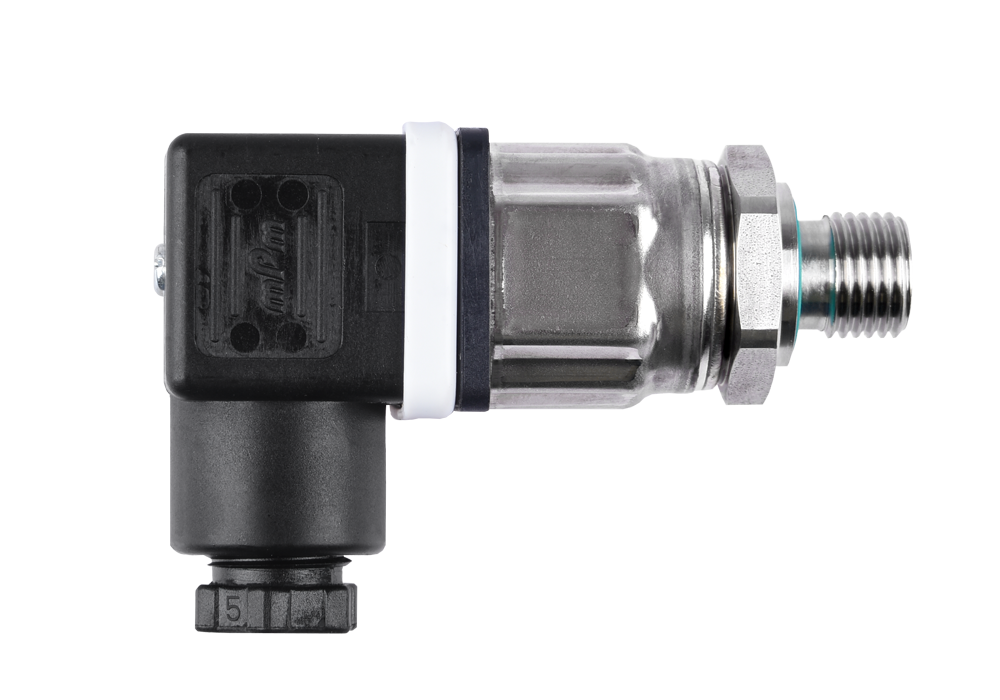

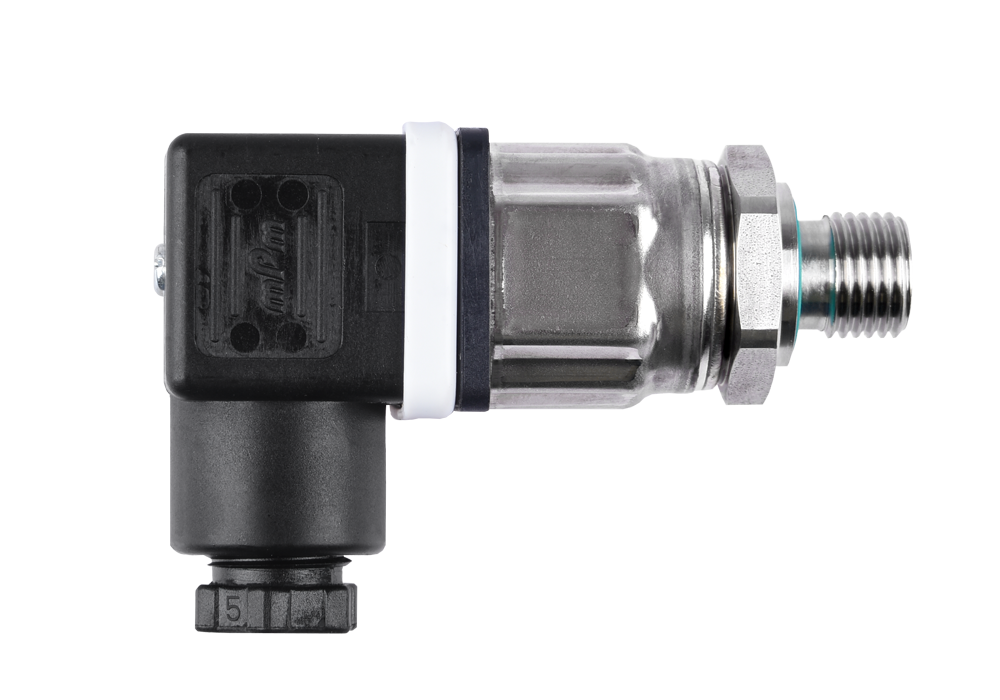

PTS 500 - for measuring of pressure and temperature

2 in 1 sensor, measures pressure and temperature in the process.

Pressure monitoring in compressed air and gas systems helps to significantly reduce energy consumption. Only a few types of machines actually require compressed air with more than 6 bar overpressure. A reduction in the nominal pressure reduces both the power consumption and the leakage losses and increases the service life of the compressor. Electricity savings in the range of 6 - 8% can be achieved by a reduction of the nominal pressure by only 1 bar.

The smaller the pressure drop across the filter, the less high the nominal pressure must be set. If the pressure drop across the filters is greater than 0.3 bar, the filters should be replaced. Our proven differential pressure sensors and pressure gauges are ideal to monitor those figures continuously.

2 in 1 sensor, measures pressure and temperature in the process.

for measurements from 0...16 bar, RS485, G 1/2".

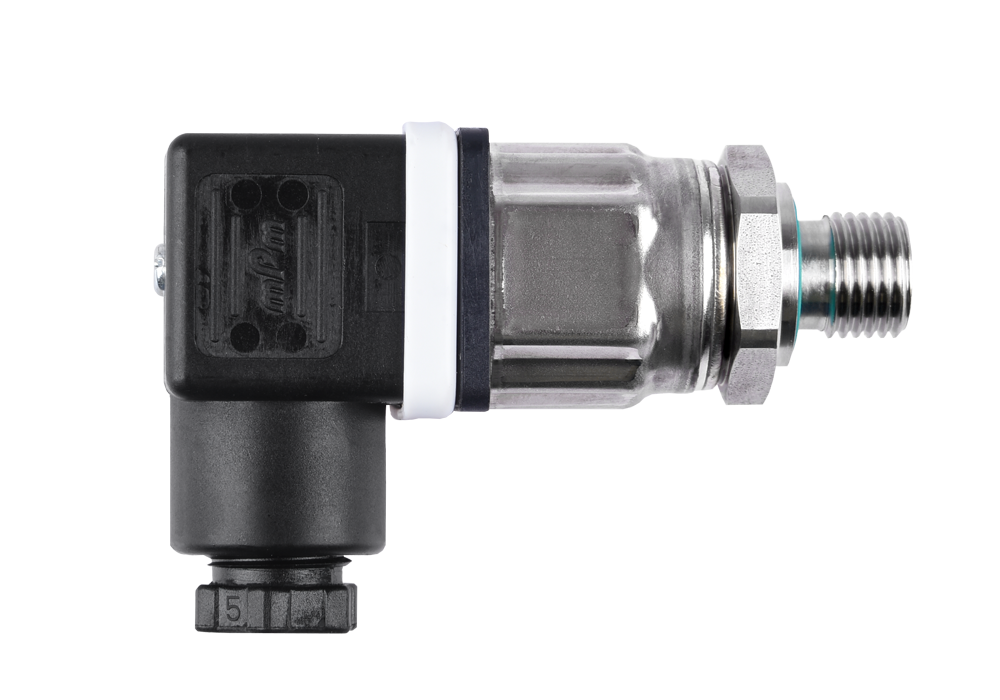

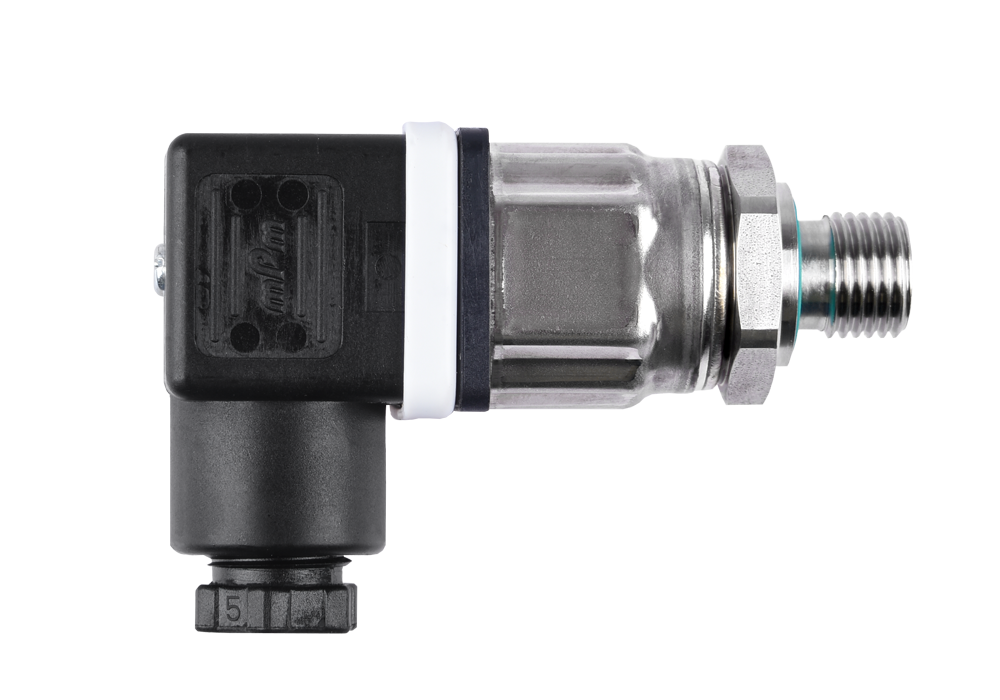

for measurements from 0...100 bar with accuracy of full scale max. 0,5 %.

This affordable differential pressure probe ensures the effectiveness of compressed air filter systems by measuring the differential pressure across the filter element (measurement of filter contamination).

(absolute pressure, temperature, rel. humidity), incl. wall bracket

for measurements from 0...1.6 bar absolute with accuracy of full scale max. 0,5%.

for measurements from -1...+15 bar with accuracy of full scale max. 0,5%.

for measurements from 0...40 bar with accuracy of full scale max. 1% or max. 0,5%.

for measurements from 0...400 bar with accuracy of full scale max. 0,5 %.