Energy management

Optimising the efficiency of compressed air systems is crucial for Industrial applications, and Measuring devices from different categories play a key role in monitoring and optimising Energy consumption.

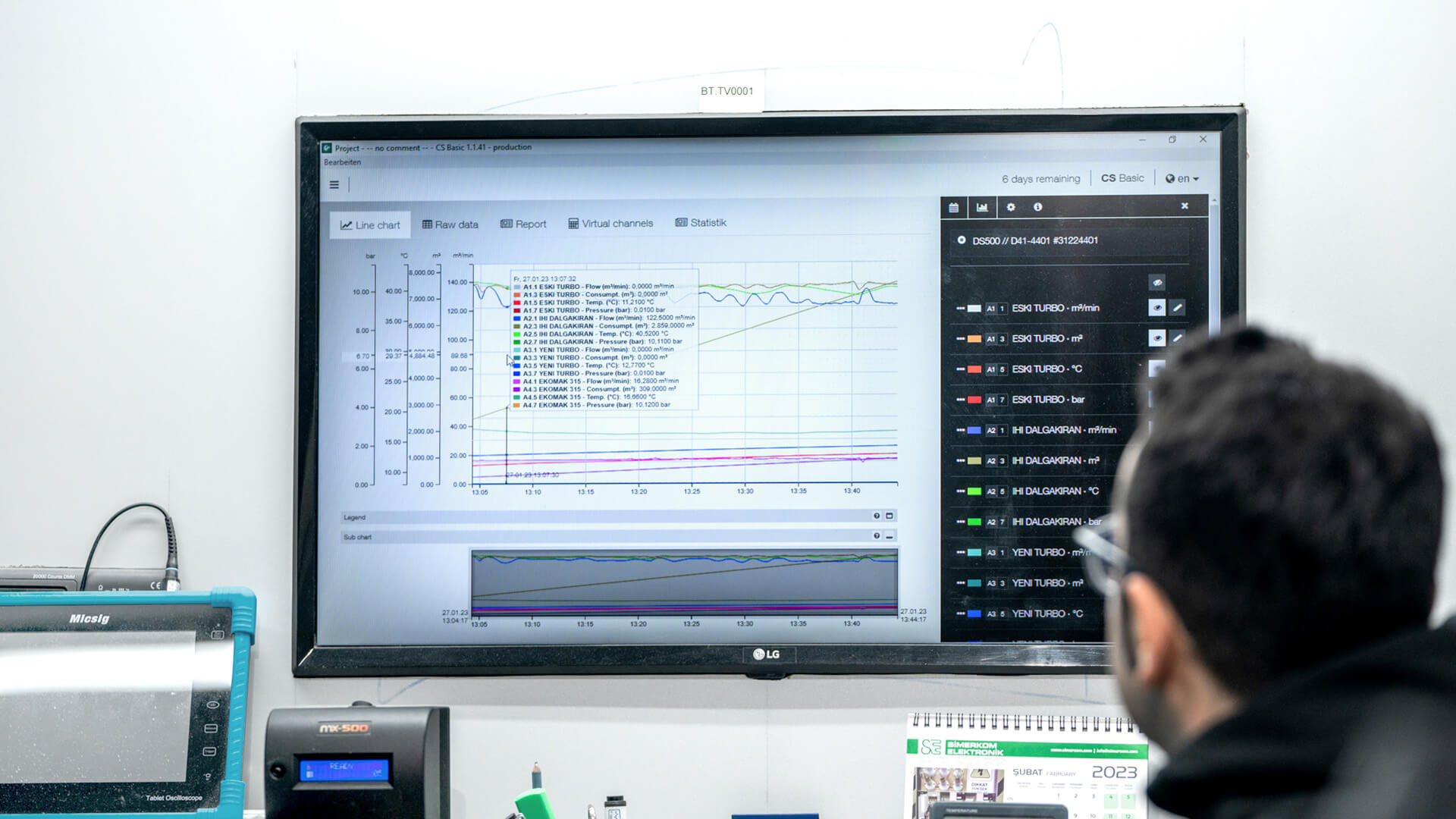

The compressed air meter enables precise Consumption measurements and forms the basis for targeted optimisation measures. Modern compressed air meters offer digital interfaces for seamless integration into higher-level control systems, enabling real-time monitoring and fast response times to deviations.

The compressed air quality monitor or compressed air quality sensor monitors humidity, Particles and oil content in the compressed air. Precise knowledge of these values is crucial to ensure that the Compressed air meets the required standards. Modern compressed air quality monitors often monitor several parameters simultaneously.

Leak detection is another aspect of efficiency optimisation. Leakage detectors localise Leakages and enable a quick response to reduce energy loss wherever necessary. Thermographic cameras such as our UltraCam also detect leaks optically, enabling an even more precise and faster evaluation of whether measures need to be taken.

Dew point measurement is crucial for Compressed air quality. Dew point transmitters continuously monitor humidity and temperature to prevent condensation and damage.

Together, these systems make a significant contribution to optimising the efficiency of compressed air systems. In the following articles, we have collected some concrete examples and best practices to make the topic a little more tangible for you.