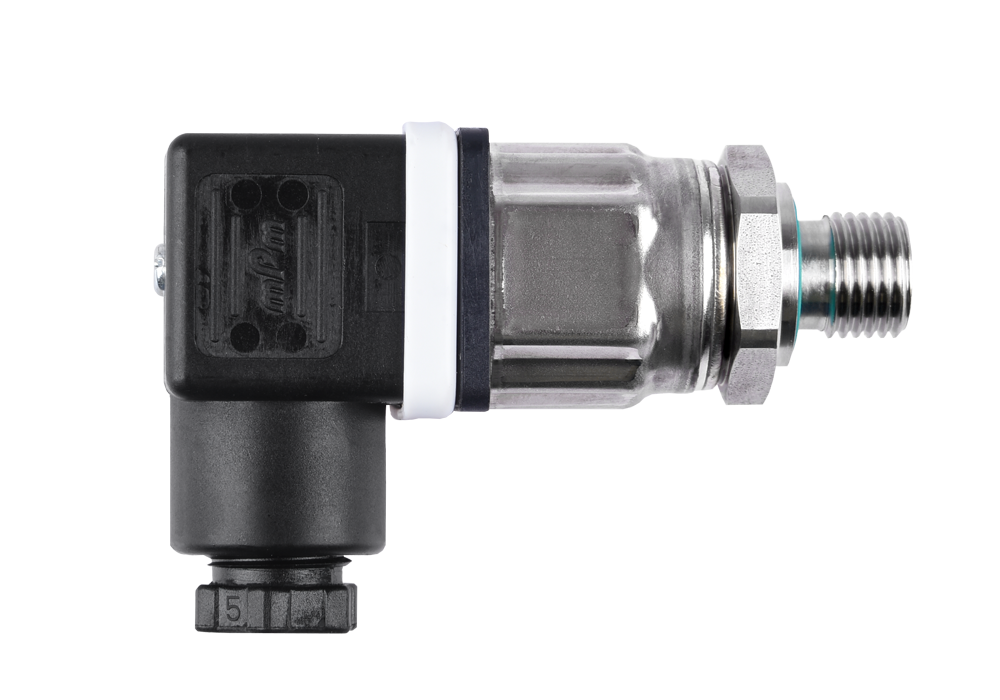

PTS 500 - for measuring of pressure and temperature

2 in 1 sensor, measures Pressure and Temperature in the process.

Monitoring the line pressure in Compressed air and Gas systems helps to significantly reduce Energy consumption. Our experience as a long-standing manufacturer of Pressure sensors has taught us that only a few machine types actually require Compressed air with more than 6 bar overpressure. Reducing the nominal pressure reduces both power consumption and leakage losses and also increases the Compressor's service life. Power savings in the range of 6 - 8% can be achieved, for example, by reducing the nominal pressure by 1 bar.

The smaller the pressure drop across the filter, the less high the nominal pressure needs to be set. If the pressure drop across the filters is greater than 0.3 bar, the filters should be replaced. Our(differential) pressure sensors are ideal for monitoring these key figures and realising the associated savings potential.

2 in 1 sensor, measures Pressure and Temperature in the process.

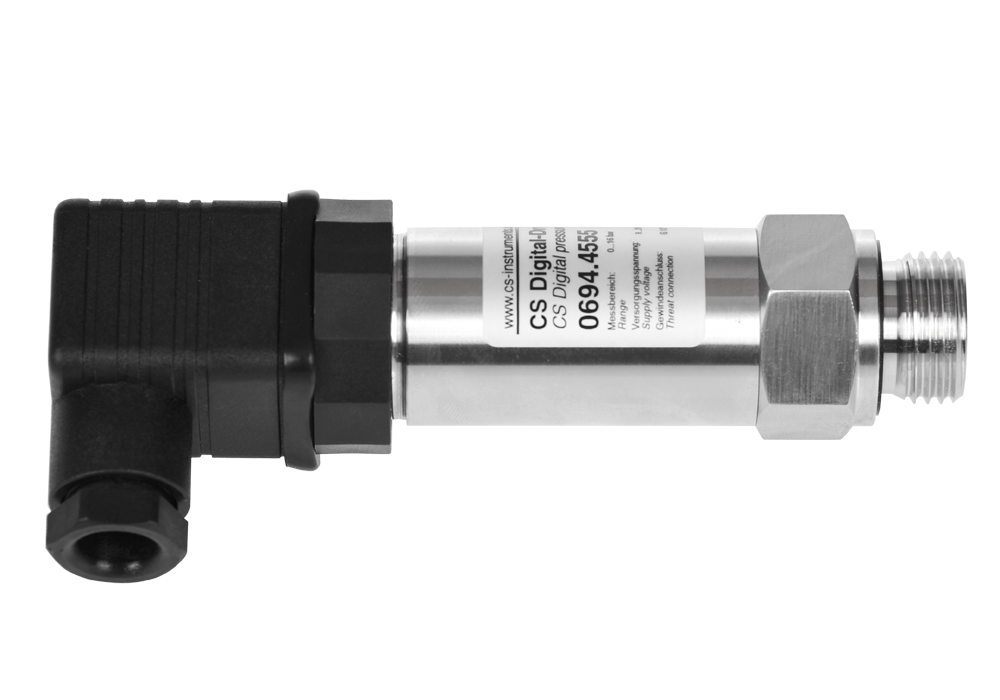

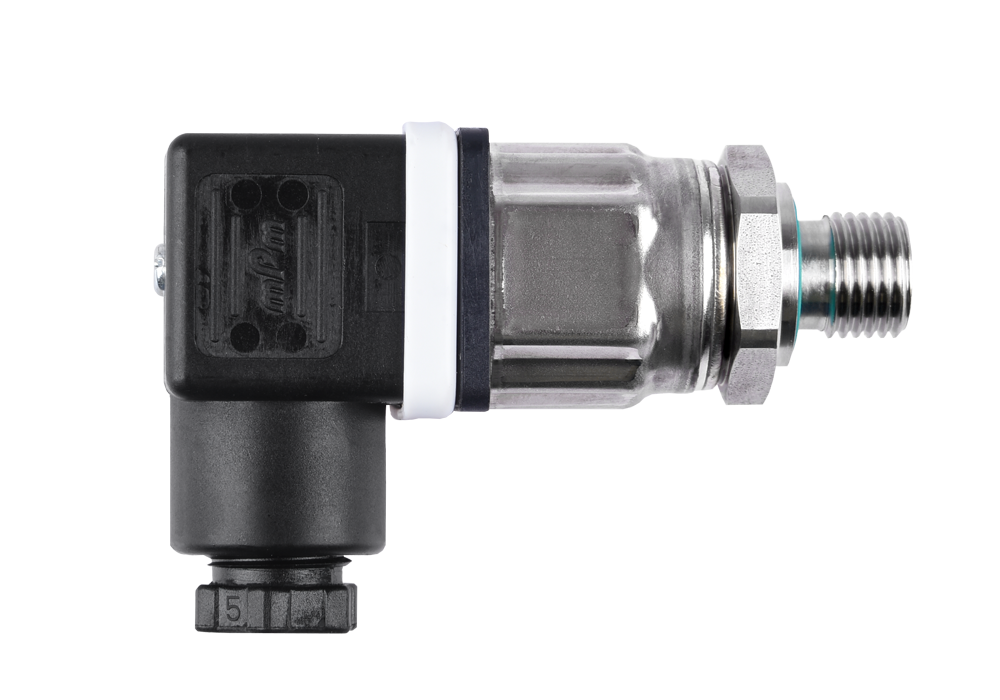

for Measuring from 0...16 bar, RS485, G 1/2"

for Measuring from 0...100 bar with an Accuracy of max. 0.5 % deviation.

Low-cost differential pressure sensor for ensuring Compressed air quality. Measuring takes place in a minimum of space with holder and base in one.

incl. wall bracket (abs. Pressure, Temperature, Rel. humidity)

for Measuring from 0...1.6 bar absolute with an Accuracy of max. 0.5% deviation.

for Measuring from -1...+15 bar with an Accuracy of max. 0.5% deviation.

for Measuring from 0...40 bar with an Accuracy of max. 1% or max. 0.5% deviation.

for Measuring from 0...400 bar with an Accuracy of max. 0.5 % deviation.