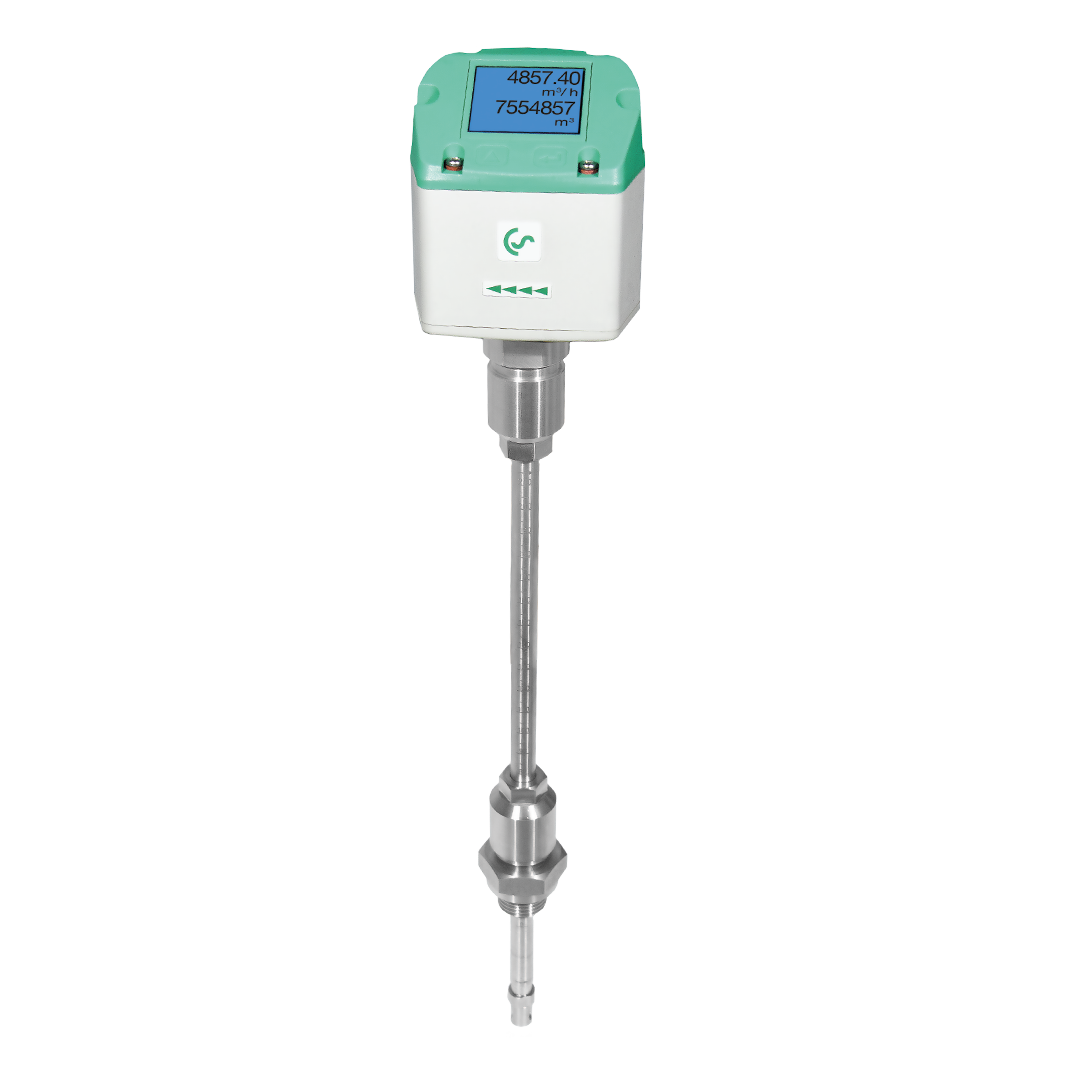

VA 500 - Flow meter for compressed air and gases

RS 485 Modbus interface, 4...20 mA Analogue output, Pulse output integrated as standard.

In summary, a bulk material is a powdery, granular or even lumpy substance that is available in a form in which it can be poured. Bulk material can consist of many materials and is defined by grain size, bulk density, roughness and Temperature. For example, building materials such as gravel, cement and sand are bulk goods, but foodstuffs such as sugar, salt, coffee and flour are also considered bulk goods.

The transport of these bulk materials requires special measures. A distinction is made between continuous and discontinuous transport. Continuous transport, for example, is ensured using hoses or pipes with compressed air as the conveying medium, known as pneumatic conveying.

The optimisation of pneumatic conveying systems is very popular today, as a lot of energy can be saved. Depending on the bulk material, treated or untreated compressed air is used for conveying through pipes and hoses; the amount of compressed air required should be monitored and minimised as far as possible. Monitoring the compressed air consumption is recommended in any case.

In addition to compressed air consumption, the quality of many bulk materials is clearly a priority. For example, the air required to convey powdered medicines or foodstuffs such as flour or sugar should be free of water, Oil or other Particles.

As in any compressed air system, Leakages can increase Energy consumption exponentially. Regular monitoring of the tightness of the system can save high costs.