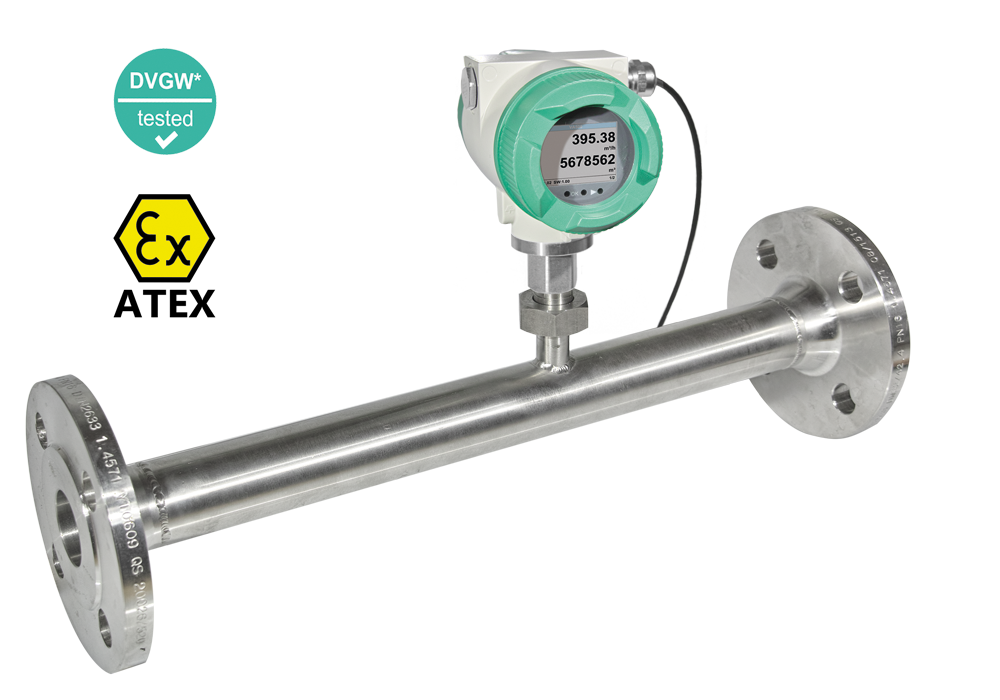

VA 570 - Thermal mass flow meter for consumption measurement

ATEX approval for hazardous areas and DVGW approval for use in natural gas.

Industrial steam boilers are used in many processes such as heating, drying, sterilization. Steam boilers, which transform the energy of combustible chemicals by transferring them to water, are also the roots of the industrial revolution.

Fuels such as coal, fuel oil and sawdust used in steam boilers are being replaced by natural gas due to environmental regulations. Thus, steam boiler efficiency is more important not only for costs, but also for environmental impact.

Basic way to calculate the efficiency of the steam boiler is the proportion of the energy of the fuel to the enthalpy of the steam obtained. The multiplication of the flow rate of the natural gas used as fuel and its thermal energy, the flow rate of the steam obtained, and its enthalpy will result in the energy equation entering and exiting the steam boiler.

Sample steam boiler efficiency calculation:

| Natural gas flowrate: | 330 Sm3/h |

| Heating value of gas: | 45.000 kJ/Sm3 |

| Steam flowrate: | 5.000 kg/h |

| Steam pressure: | 6 bar(g) |

| Steam enthalpy: | 2.763 kJ/kg |

| Heat power: | 330 x 45.000 = 14.850.000 kj/h |

| Steam power: | 2763 x 5000 = 12.433.500 kj/h |

| Efficiency: | 12.433.500 / 14.850.000 = 84% |

To make the above calculation, it is necessary to measure the natural gas flow rate at the inlet of the boiler in Sm3 (standard cubic meter) and the steam flow rate at the outlet in kg/h.

CS INSTRUMENTS VA570/520 thermal mass flowmeters measure natural gas flow in Sm3. Thus, they can be used as submeters without the need for an extra corrector device. Steam flow, pressure and temperature at the boiler outlet can be measured with the VX570 vortex flowmeter. So, the necessary flow parameters for the input and output energy balance are obtained.

The mathematical calculation function of the DS500 data logger to be added to the system will be used to calculate the boiler efficiency above and record the instantaneous values. The performance of the boiler at different loads and conditions will be easily monitored.