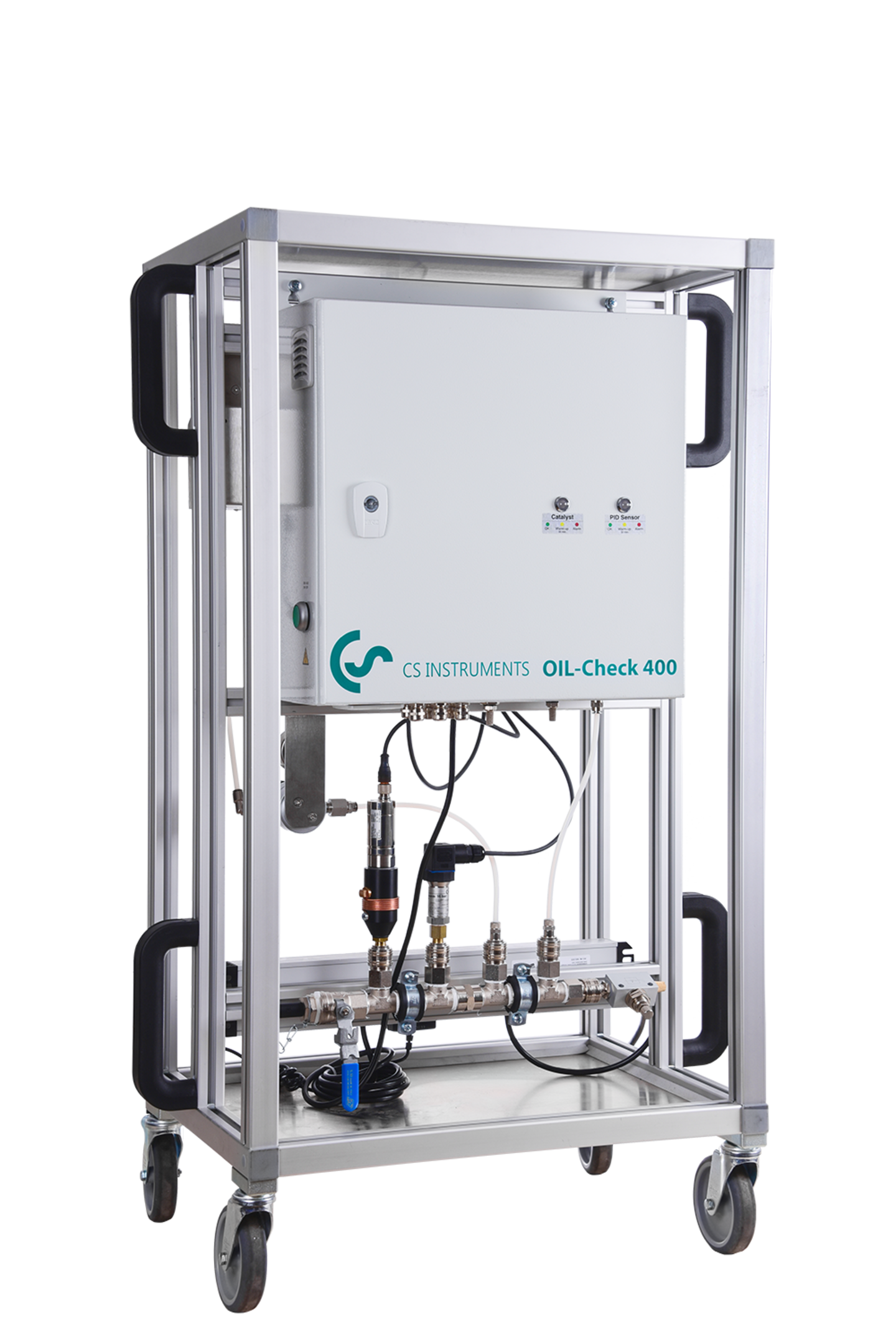

Residual oil content measurement OILCHECK according to ISO 8573 - mobile solution

The residual oil content sensor OIL check measures the vaporous residual oil content in the compressed air. By means of a sample taking a representative part volume flow is taken from the compressed air and led to the OIL check. Due to the continuous measurement threshold value exceeding will be recognized immediately and remedial actions can be initiated to ensure

oil-free compressed air.

- Ideal for mobile measurement: The PID sensor is ready for measurement within about 30 minutes

- OIL-Check 400 – residual oil measurement of the vaporous residual oil content from 0.001…2.5 mg/m³, 3…16 bar. Highly precise PID sensor, integrated mini catalyst for zero point calibration

- Mobile transport trolley including roles (outer dimensions: 1.0 x 0.7 x 0.35 m (W x H x D) with firmly mounted components of OIL-Check 400, PC 400, FA 510

- Mobile sampling system consisting of 2 m PTFE hose, quick lock coupling (oil- and grease-free)

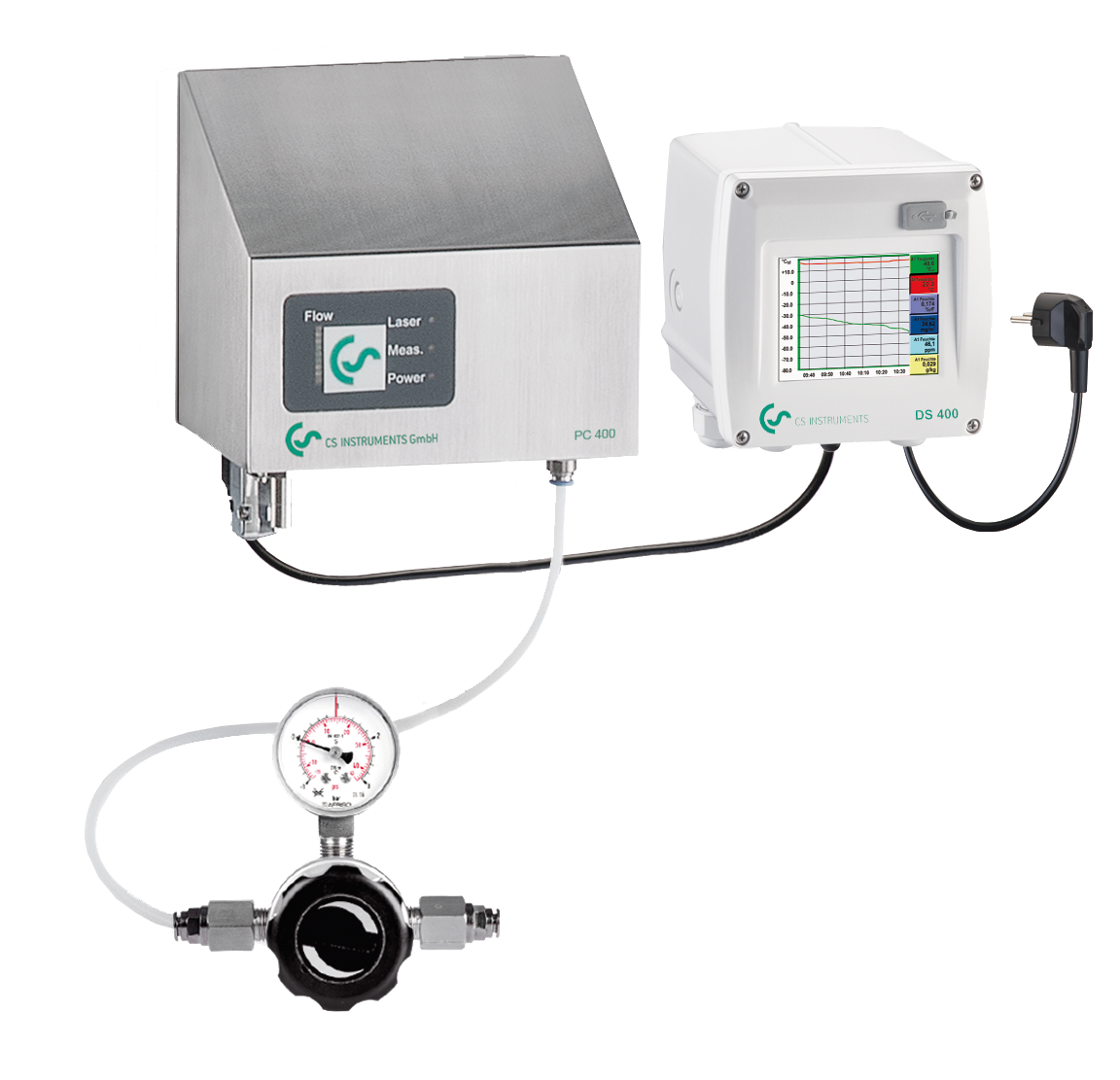

- PC 400 particle counter up to 0.1 µm for compressed air and gases, incl. pressure reducer/sampling hose, calibration certificate, Modbus-RTU interface

- FA 510 dew point sensor, -80°...+20°Ctd, incl. mobile measuring chamber and 5 m connection cable to portable devices

- DS 500 mobile - intelligent chart recorder with 4 sensors inputs

- CS Basic - data evaluation in graphic and table form - readout of the measured data via USB or Ethernet. License for 2 working places